NAAC®

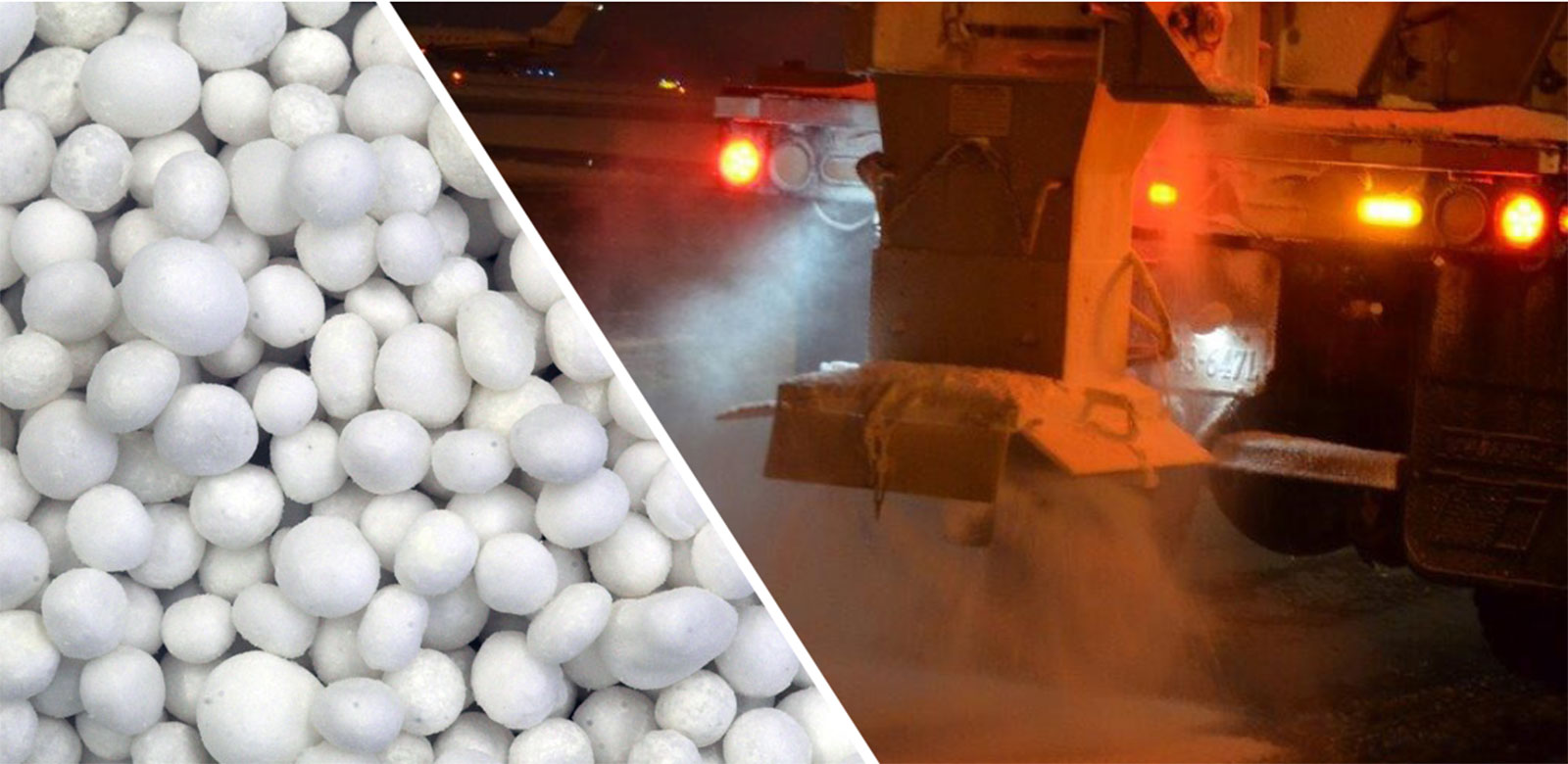

Solid Deicer

AMS 1431 Certified

NAAC® is the leading premium deicer because it is exothermic, releasing heat as it dissolves. Burning through the snow and ice pack, it breaks the bond with the surface to keep it snow and ice free. Its low working temperature and long residual holdover keeps it working longer.

Benefits

- Works longer, requiring fewer applications

- Less damaging to concrete, steel, and vegetation than common deicers

- Manufactured using high-grade, chloride-free raw materials

- Produced as a round pellet to penetrate ice efficiently and produce less dust than irregular-shaped deicers

- Complimentary customer training upon request

Performance

- Gives off heat as it dissolves - exothermic

- Patented Unipel technology ensures uniform size, shape, and composition of each pellet

- Penetrates directly to the pavement due to spherical shape; irregular shaped deicers penetrate laterally, inefficiently expending energy before reaching the pavement

- Requires less material than common deicers to achieve similar effectiveness

- Active to low temperatures 0°F (-18°C)

- On roadways, NAAC weakens ice by changing the structure enabling the ice to be broken up by traffic action

Environment

- Biodegrades quickly at low temperatures, will not accumulate in the environment like chloride salts

- Low toxicity to fish and mammals

- Less persistent in the environment than sodium formate

Application

- Airport Deicing Typical Application Rate - apply in uniform patterns:

- Near 32°F (0°C) on thin ice = 5-7 lbs/1000 ft² (25-35 g/m²)

- Less than 10°F (-12°C) on thick ice = 10-25 lbs/1000 ft² (50-75 g/m²)

- Highway, parking lot, and other commercial application rates are typically lower than airside because of pavement type, surface conditions, traffic action, cycle time, and level-of-service expectations

- In general, apply like salt and adjust with experience

- Re-apply when new accumulation shows first tendency to bond

- Plow once bond is broken

- Prewetting - airports and commercial users may apply Cryotech E36® and CF7®, respectively, to NAAC at spreader outlet at a rate of 10% by weight

Cryotech NAAC® Shaker Jug – Special Packaging

All-in-one, ready to use for ramps, jetways, doorways, baggage handling areas, helipads, residential use, and more

- Lightweight & Convenient

- User-Friendly

- Maximize Performance